AIMCAL presents 2022 Product of the Year, Technology of the Year and Sustainability Awards

By Contributing Editor Hallie Forcinio

The Association of International Metallizers, Coaters and Laminators (AIMCAL) honored its 2022 Product of the Year, Technology of the Year and Sustainability Award winners at a ceremony during the 2022 AIMCAL Executive Leadership Conference (April 4-5, 2022, at the NASCAR Hall of Fame in Charlotte, NC).

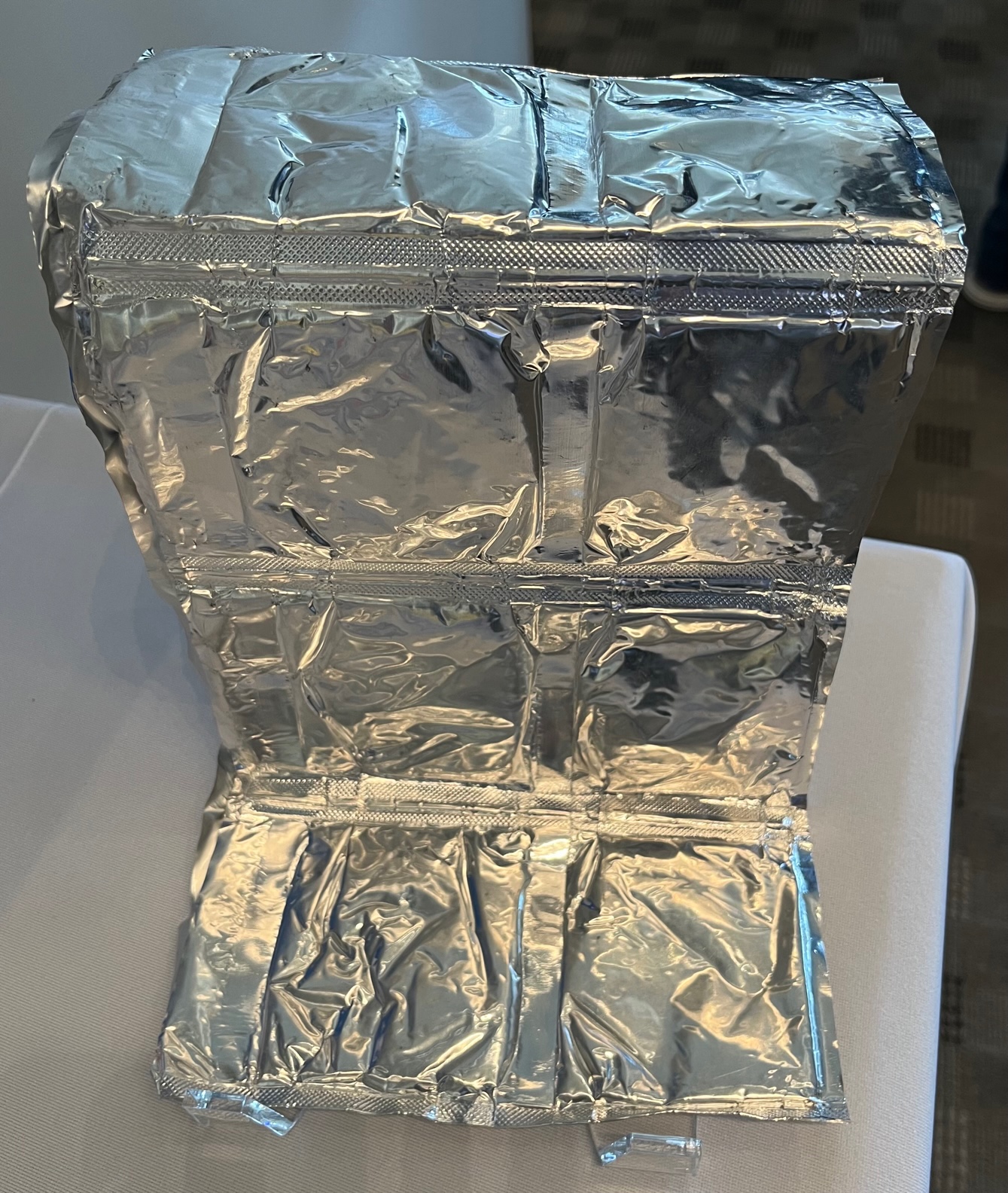

The 2022 Product of the Year Award* went to the ProAmpac Holdings, LLC, Flexibles Div. (Cary, IL), for a quilted, multilayer film/foil phase-change mat used to insulate attics in residential, commercial and industrial buildings and reduce energy costs for heating, cooling and ventilating by up to 50% (see above).

The eco-friendly, nontoxic QE Platinum material produced for Syndego LLC is a patented and patent-pending quilted mat of pillow pouches filled with proprietary phase change material (PCM). The structure controls the temperature differential across the R-value instead of the traditional method of limiting heat flow by adding more R-value. Easily installed on top of existing insulation and designed to be effective for 20 years, the QE Platinum mat is positioned foil side up so the foil serves as both a radiant and moisture barrier. Additional energy control is provided by the PCM in the pillow pouches, which melts and serves as a heat sink to hold energy until the temperature in the space decreases. The PCM then re-solidifies and releases the stored energy. The PCM melt point is designed to be just above the ideal temperature for the area and minimizes temperature extremes. Maintaining a more consistent temperature can flatten kilowatt-hour (kW) usage and cut energy costs and, thereby, reduce the operation’s carbon footprint. Other applications include cold-transport vehicles and cold-chain storage.

The judges liked the combination of technologies to achieve an improvement over existing insulation options and the potential for significant energy savings. “The material also is easy to install and reduces the amount of toxins and irritants released into the environment,” noted one member of the panel.

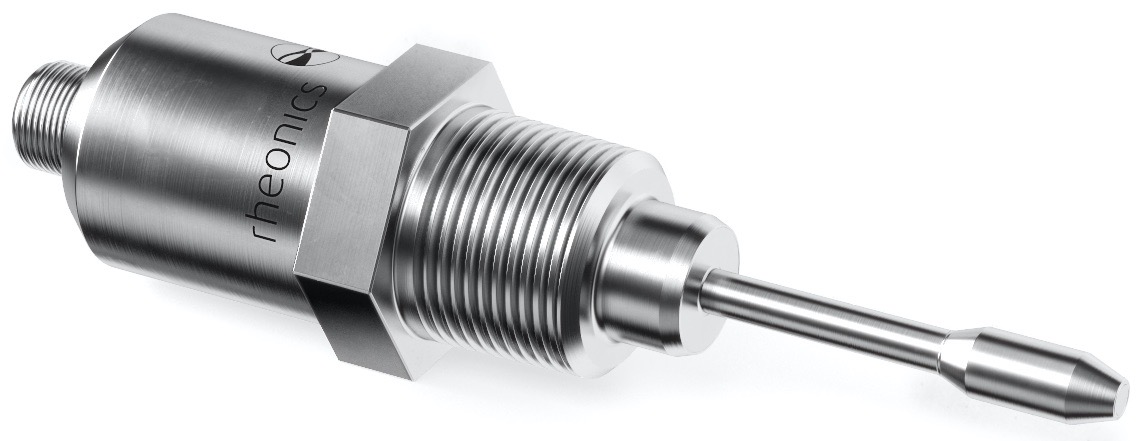

The 2022 Technology of the Year Award went to Rheonics (Winterthur, Switzerland) for its InkSight multi-station, ink viscosity-control system for printing presses. The Rheonics InkSight system delivers quality, cost and environmental benefits by managing all viscosity measurement and control functions, thereby allowing operators to focus on quality rather than measurement.

In operation, an SRV sensor detects changes in ink viscosity and transmits a signal to the control cabinet. The Rheonics predictive tracking controller monitors viscosity, predicts the rate of change and operates a valve to dose solvent as frequently as every 20 seconds to compensate for changes due to temperature fluctuation, evaporation or the addition of fresh ink. The ColorLock software and graphical operator interface allow viscosity to be locked to the desired color density. Automating ink viscosity control reduces setup time and scrap, maximizes print quality and accurately doses solvents, potentially reducing emissions. The compact system integrates easily, offers a high level of accuracy and stability and requires no recalibration, cleaning or maintenance. Compatible with inks, primers and adhesives, the technology also is used in an array of coating operations.

The judges also awarded a Technical Excellence Award to InkSpec (St. Bruno, Quebec, Canada) for its InkSpec MIIS-V3 viscometer, model 40339-2200, a patented and patent-pending device that measures and controls the viscosity of process fluids. Based on acoustic suspension technology, the unit is unaffected by flow, micro-foaming or machine vibration. The small, light sensor can be installed in tight spaces and mounted vertically or horizontally. Primary applications include flexographic, gravure and corrugated printing; food and beverage can coating; sheet coating; and medical device printing and coating. Other commercial applications include adhesives, gloss and coefficient of friction coatings for offset printing; glass, mirror and eye glass coating; and industrial laminating.

The judges had a lengthy discussion about the merits of each Technology of the Year candidate. For the first time in memory, with two submissions with similar functions, they also consulted an expert in coating and material development processes. After considering that input, the judges decided the comprehensive nature of the Rheonics technology, as detailed in its technical writeup, deserved the Technology of the Year Award, but the InkSpec technology also warranted recognition. Noted one judge, “The Rheonics system offers control over a wide range of viscosities and has the potential to reduce waste due to off-spec color caused by changes in ink viscosity.”

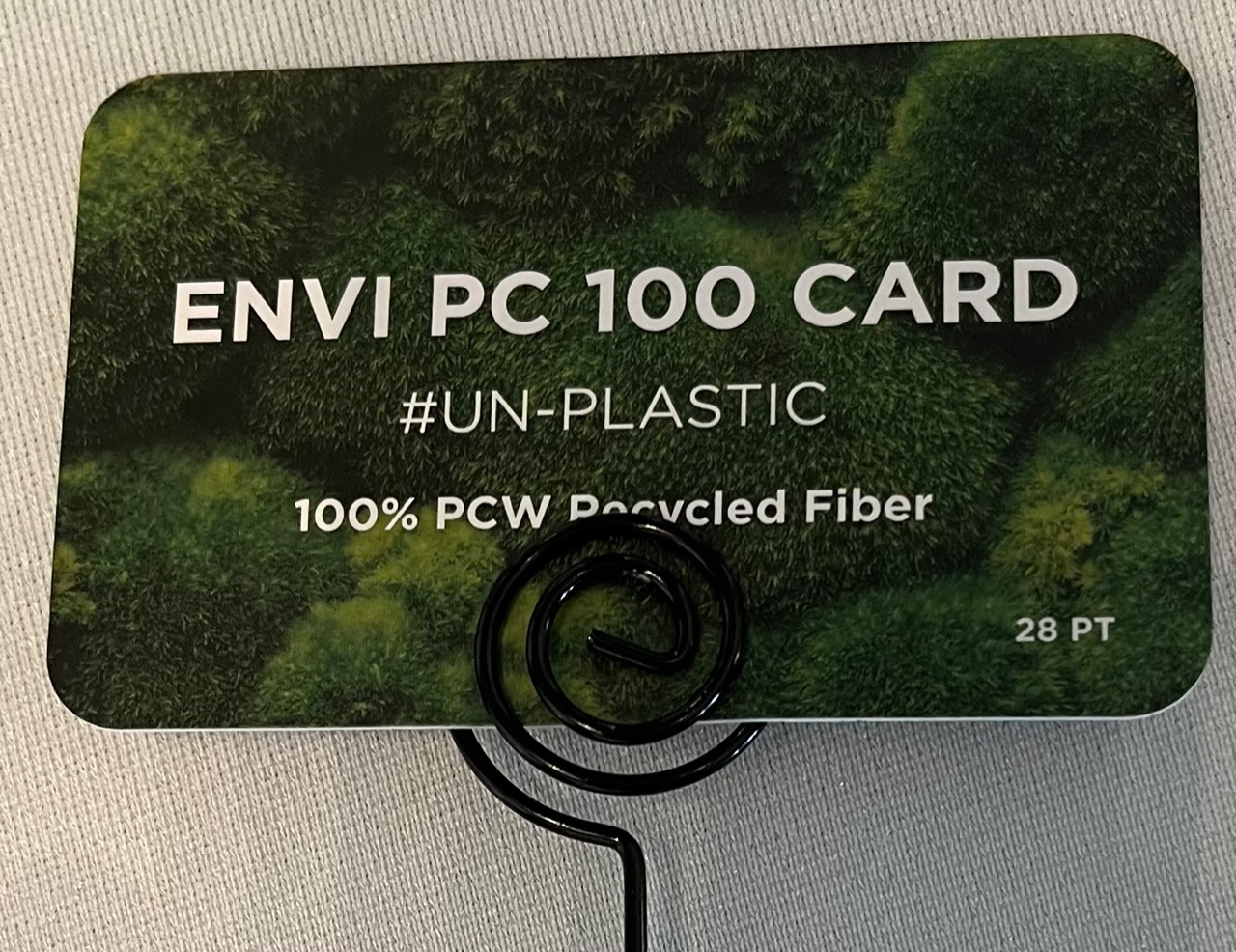

The 2022 Sustainability Award went to Monadnock Paper Mills, Inc. (Bennington, NH), for a 100% post-consumer-recycled (PCR) fiber stock for gift/loyalty cards. The 28-point Monadnock Envi PC 100 Card material is a coated/laminated structure engineered for dimensional stability, durability, printability and performance equal to all-virgin-fiber cards. It can accommodate magnetic stripes, scratch-off and signature panels and maintains the structural integrity needed to allow affixing to a carrier with fugitive glues and damage-free removal by the consumer. Designed with maximum PCR content as an alternative to polyvinyl chloride, polylactic acid, virgin-fiber solid bleached sulfate and mixed virgin/recycled fiber cards, the Monadnock Envi PC 100 Card is renewable and has been independently verified as recyclable in curbside bins. Other potential applications for the PCR material include hotel keycards, near-frequency communication (NFC) cards and radio frequency identification (RFID) cards.

Members of the judging panel were excited by the prospect of replacing billions of plastic cards that aren’t easily recycled with a renewable, recyclable alternative. They also noted the card’s attractive appearance and durability. “I really had to work at it to tear it,” noted one member of the panel.

Competition judging panel

Judges for the competition met via Zoom in a session moderated by AIMCAL Executive Director Chris Kerscher. Members of the judging panel included experts in converting and packaging: Dr. Charles A. Bishop of C.A. Bishop Consulting, Ltd. (Loughborough, U.K.); Larry Jopko, principal of Stickum Consultancy LLC (Houston, TX); Robert M. Kimmel, Sc.D., associate professor, director, Packaging Science Program, director, Center for Flexible Packaging, Department of Food, Nutrition and Packaging Sciences, Clemson University (Clemson, SC); and Steve Lange, managing member of ProcessDev LLC (Cincinnati, OH).

Dr. Bishop established C.A. Bishop Consulting, Ltd., in December 1998 after earning several degrees and working for Imperial Chemical Industries. He specializes in all aspects of vacuum deposition including system design; process development, scale-up and troubleshooting; process control; and plasma surface treatments and coatings. He has authored many technical papers and books, holds five patents, and conducted training courses around the world.

Jopko has been involved in the flexible packaging industry for more than 40 years and retired from Dow Chemical Co. (Lake Jackson, TX). As a specialist in food and industrial packaging and an expert in urethane, acrylic, and polyester adhesive and coating chemistry, he has helped develop products, structures, converting and application methods, as well as suitability testing protocols.

As part of the Clemson faculty since 1999, Dr. Kimmel teaches package design, supervises research and service to the industry in flexible packaging, and maintains an active consulting practice as an expert witness for intellectual property litigation. Earlier in his career, he worked for more than 30 years in R&D and management positions at Hoechst Celanese Corp. focused on films and resins, primarily for the packaging industry.

Lange is the managing member of ProcessDev, LLC, a manufacturing-process consultancy. He retired as a Research Fellow from the Procter & Gamble Company (Cincinnati, OH), where he spent 35 years developing web-converting processes for consumer products and as a trainer of web-handling, modeling/simulation, and data analytics.

* The AIMCAL Product of the Year Award honors the late Peter Rigney, former publisher of Paper, Film and Foil Converter and long-time champion of the competition, who passed away in 1997.